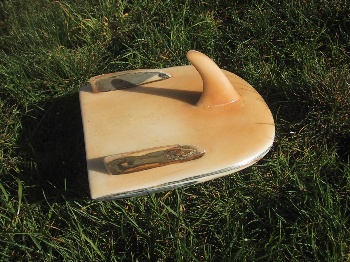

The Mitt mold reciever, seen above with the lid during fabrication, and below after final coating. The lid will hold the Mitt in suspension while the latex rubber mold is poured. The reciever will then be the framework which will hold the rubber mold in shape while the hand layup is done.

The Mitt hit a spedbump and needed to have the guts of the paintwork removed. The spray paint that had been used just hadn't cured hard enough to be smooth sanded, and later the under surface became noticeably soft and insecure, so I chopped it out and filled it with epoxy. The mistakes made are multi faceted, but basically, the initial fabrication was done casually with cheap plywood and old spray paint. Originally, the Mitt was built as a demo, then the decision to do a marketable model was born; so the whole process was handicapped by the poor starting point. The paint issues continued after the work done below.

All of the final shaping became impaired by the paint under the surface. After the epoxy I began doing resin build up for sandable body, but as the shaping was fine tuned, the paint underneath continued to plague the progress. The finer shape required ongoing paint removal, as seen below.

Each step along the way revealed another area needing a tune up. The shots above and below show the old shape tracking fins before they were deepened and lenghtened. Note the sharp end. The rounded steering fin Is coming along though.

The rounding of the tracking fins opened up a new can of worms, and eventually required the entire removal of any and all white spray paint, and at times all of the paint and a bit of the ply, just to give clearance for thinner longer fins.

If I'd started with the deliberate intention of making a prototype, this would have been avoided and I'd be kicking wave butt right now. I work on this daily, and expect to pour the rubber as soon as the model is sharp enough the pass our expert scrutiny.

Spring '08

WHAT THE #@$*#%& IS TAKING SO LONG ??!!

.